In order to categorize a shoe, we must look at the upper, the heel and its functionality.

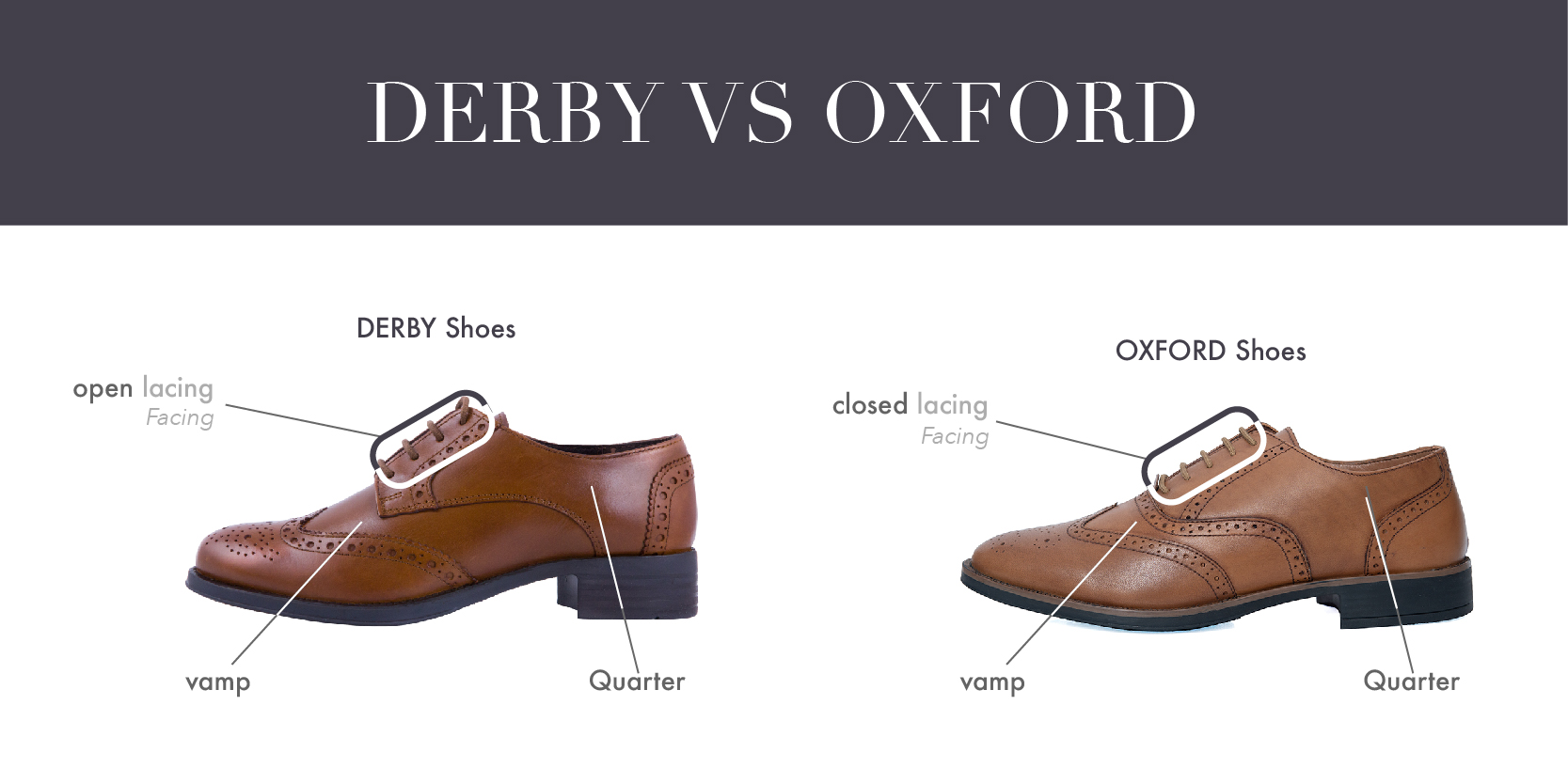

The Derby shoe can be identified by the fact that it has the quarter (also called the back part), is stitched on the vamp(also called the front part), usually over, with stitching ending in the part of the shoe that contains the eyelets, known as “the facing” with a special lock stitch. The advantage of this type of construction is in the fact that the facing is free to open and close, just like flaps, giving the wearer a great deal of comfort in the instep area. It is understood that the vamp area of the Derby shoe can have various designs and shapes but they all have in common the comfort opening of the facing. The simple fact that the facing is open (also said open lacing), makes this type of shoe a more Casual shoe. We can have a Men’s Derby, a Women’s Derby and a Children’s Derby.

The Oxford shoe is the opposite of the Derby and so, it is the front part (the vamp) which is stitched on the quarters and so blocking the facings from opening freely at the bottom, making a V shape opening from top to bottom. The Oxford for this reason is a much more classic formal type of shoe and not as comfortable to wear as a Derby shoe. The Oxford also comes in various designs and shapes but all have in common the fact that they all open from the top center facing and locked at the bottom with a vamp stitching giving a narrow V shape opening. Like the Derby, the Oxford can be made for Men, Women and Children.

In both cases, Derby or Oxford, they come in various models and shapes. A general rule of the thumb is that the Derby is casual and the Oxford is formal but that does not stop the creativity of the designers to make a oxford shoe on a sneaker design giving it a very sporty look or make a classical derby. The limit to its styles depends only on the imagination of the designers.

FUNCTION: The Derby shoe is a very comfortable and functional shoe. It is usually a casual shoe but if needed can also become a formal shoe with slight modifications in the design. We strongly suggest using this kind of shoe for the corporate use where staff need to stand up or walk for long distance. It also is a perfect shoe for fight attendant due to the fact that during long flights and sitting for long period, the foot usually swells and so you can easily relieve the pressure by loosening the shoe laces. On the contrary, the Oxford shoe has a fixed opening and so by loosening the shoe lace will not make any difference since the opening is fixed by the vamp covering the quarter. In case a more formal shoe is required in the corporate use, we could suggest to make a formal derby shoe having the look of a classic shoe but the comfort of a derby shoe. It is important to know that for each type of shoe to get a perfect fit, you will need to modify the last orelse you won’t be able to get the maximim comfort deserved and much appreciated.

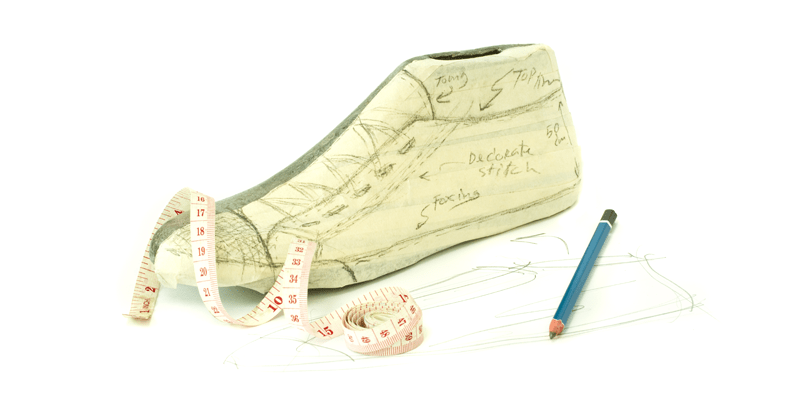

Italian Footwear Solution always discuss with our customers to understand perfectly their needs since the foot should not adapt to the shoe but it is the right shoe which needs to adapt to the function it will endure. After receiving the correct information, we will suggest which shoe will better fulfill the needs and ensure the size/width are in accordance to the customers’ needs and requirements. One shoe fits all approach does not work and we understand that the most important thing is to listen to our customers, then fulfill their requirements and working together with best Italian technicians and materials to offer a beautiful esthetic shoe having in addition a perfect most comfortable fit.