BASIC-Shoe Pattern Design

In order for a shoe manufacturer to cut the material for the making of the shoe upper, we need to first make a shoe pattern design which allows them to produce the cutting knifes which will be utilized with a specialized press to cute out the exact shape of the upper pieces. The cutting of the shoe upper materials can also be done by hand.

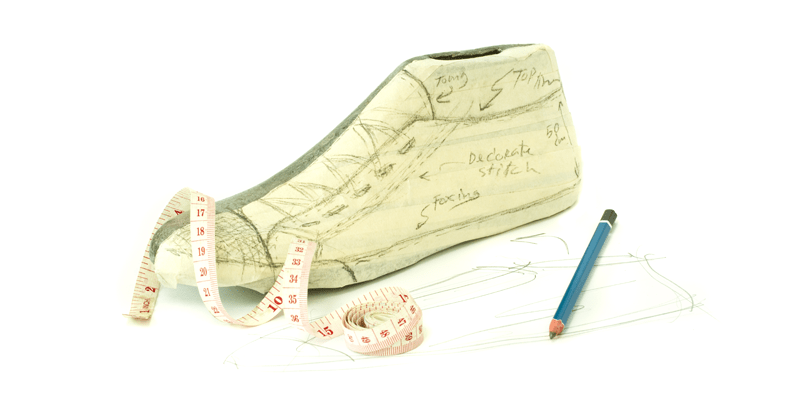

The shoe Designer will first choose the specific last made for that particular shoe we need to produce and wrap half of the outer side of the last with masking tape. Some shoe designers prefer to wrap the entire last but this is only a choice of speed in execution. Once the last is wrapped with masking tape, it is important to ensure to remove the wrinkles by pressing a pen or the handle side of the cutting knife on the masking tape and try to flatten it as much as possible. It will be difficult to get your masking tape perfectly curved around the heel and instep so you can make small cuts in the masking tape in these areas which will help around the curves. You must now draw a line on the masking tape in the middle and all around the edges of the last. This designer will first cut the excess masking tape around the edges removing the excess tape. A metal rasp can also help during this process. Once the excess masking tape is removed around all edges, you can now cut the tape following the middle line. At this point, the first shoe pattern design is done which will reflect the same design as our specific last but in 2D instead of 3D. We can now remove the masking tape from the last and place the sticky side on a flexible thin cardboard. You can now draw your pattern around the masking tape design onto the cardboard remembering to leave extra allowance space around the heel profile of 22mm, the opposite side of the instep 18mm and the toe area 10mm. This will serve to give extra material at the bottom side in order to wrap around the assembling insole during the mounting process.

Now you can cute out the new shoe last pattern out of the cardboard and you have your first shoe pattern. You can now make a test by placing it on top of a normal paper and cut out the design. You will have made from this paper a right and left side of the last. We now need to tape them together in order to create the complete upper. You can unite both sides with the help of masking tape leaving the top and bottom completely opened from which the last will be inserted. This will create a trial copy of your final upper. You will need to wrinkle the paper at this point in order to make it more flexible and manageable during the trials on the existing last. This paper upper will be stretched around the last to study any imperfections and it is during this process that any fine adjustments can be marked on the paper pattern. This is the final phase which is very important to make any adjustments to ensure we have taken all the correct measurements and that the upper will fit perfectly on our last. Once we have adjusted the paper pattern and are confident that the paper fits exactly, we can draw around the bottom edge with a pencil a line to identify the edges once we flatten the paper on the cardboard. We will then cute off the modifications added and flatten the paper pattern on a new cardboard and redraw the corrected pattern. We can now add small cuts with our knife above the drawing edge line we made previously to indicate the limit of the lining of the upper since the lining will be shorter.

You have finally completed your Shoe Design Pattern and can give it the same code number/name of your last.

The SHOE LAST is the heart of shoe design (shoe pattern) and shoe fit by reflecting the anatomical shape of our foot. If you have a good shoe last and make a perfect pattern design from it, you can be sure a great shoe will be made. A comfort Fit must be calculated each time a last is developed and is essential in producing shoes which will have the PERFECT FIT.

FUNCTION: The Shoe Pattern Design will be our guide to cut out the upper and lining. A good well-made shoe pattern design is the heart of the shoe fit and look. It will allow us to facilitate and speed the cutting of the upper materials while reducing waste.

Italian Footwear Solution will ensure the calculations and measurements of the shoe pattern designs always follows the Perfect Fit Rule remembering to get a fantastic shoe design giving the fashion element in a Comfortable and technically well-made shoe.