BASIC-The shoe construction

There are various ways to construct a shoe and each one is good for the finality of the shoe. The more complicated the more costly because of labor involved. The easiest one is the so called Cemented construction. The cemented construction is the easiest and fastest way to make a shoe. This is industrialized and you can pull (also said last) the upper around the last and fix to the bottom insole. The leather will not cover entirely the bottom insole (in order to save material and cost) so leaving a gab in the middle. In order to make it flush, we will fill this gab with a filler made of past of leather or cork or other material.

The insole in most cases, is made out of carboard. The forepart of the insole is flexible so to flex during natural walk while the back part is rigid giving stability to the shoe. In order to increase this rigidity and stability, especially with lady shoe which has a heel, an additional reinforcement will be there in the back part middle called shank. This shank is made of metal or fiberglass (tpu or nylon). A perfectly made insole will follow the bottom curvature of the last adhering perfectly to it. Very few specialized insole manufacturers will make a customized insole for one particular last and make it with the upmost precision. We need to remember that the insole is the core and main skeleton of a shoe giving it a perfect balance with all other materials. Since the upper material, including the insole, the toe box and back counter must all fit into the outsole, it is natural to understand that the outsole must be wider of a few mml in order to make all these components fit perfectly inside. In order to make a perfect insole which will fit perfectly to our particular last, the insole manufacturer will have to make one metal die for each different last. Because this is very costly, many footwear suppliers use preexisting insoles which causes the foot to suffer severe pain.

We can also have an insole with a platform which will then be covered by the upper and bottom covered by the outsole. In the case of a sandals with straps, a perfectly made insole for sandal will have incisions to allow the straps to be fitted perfectly inside and so to avoid bumps and deformity.

During the manufacturing process, we need to fix the insole to the last and this can be done with nails, staples or adhesive tape. In all these cases, they must be removed before the outsole is assembled. Once removed, the bottom part can then be sanded and smoothened in order to get a very good adhesive with the outsole. This will ensure that the attachment to the outsole with glue will be as perfect and strong as possible.

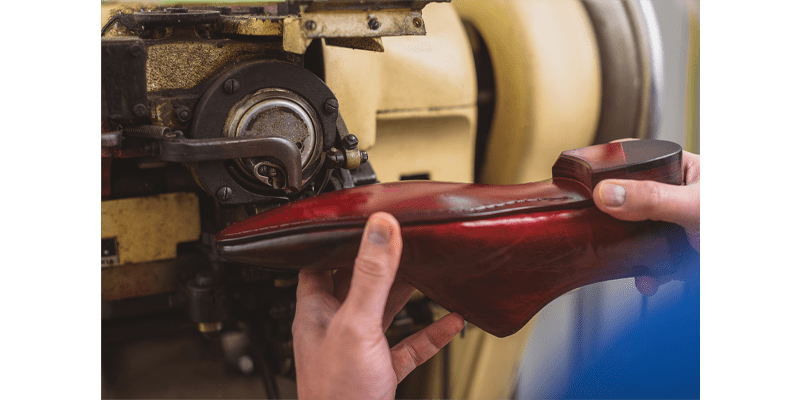

An insole with heel will have a dent in the back part called heel seat to allow the heel to fit perfectly in this position. It is important to know that also the heel must be perfectly calculated and this is done by another manufacturer specialized In heels. By placing the finished shoe without heel on a special heel calculating machine, the technician will be able to develop the perfect heel to fit perfectly to this structure. It will calculate the heel height according to the toe spring and other measurements.

We can now classify different type of heels; we have the so called breasted heel which has the tail in the back covering the front part of the heel. We can also have the attached heel. In this case the outsole can stop where the heel begins or the insole will be slimmed down to fit under the heel. We can also find a prefabricated outsole with heel included. Here there is no attachment since they are one piece all together.

FUNCTION: As we already said in many occasions, the construction of the shoe will depend on the good quality of all its materials and manufacturers making those materials. Each component is an essential part of the puzzle to manufacture a good shoe. If any of the components are of poor quality, the result will not only be visible but even worse, very painful during the entire walk for the entire life of the shoe. Good materials come from specialized material manufacturers like heels, insoles, counters, toe puffs, leathers and so on. These materials have been perfectioned in time using old tradition by passionate craftsmen. A good sole for example should be lightweight and flexible making the user feel almost as if, they are not wearing a shoe and should follow the natural movement of the foot during walk. The upper materials used should be of highest quality, soft and anti-allergic to embrace the foot without any compression in any point with function of following the foot during walk. The fit of the shoe must be the most important calculations the designer should focus on during the creation. The correct measurements of the foot circumferences and length, will allow the designer to manufacture any style of shoe having a very comfortable fit. These calculations take into consideration the walking movement, the standing position and also the sitting position which are obviously different due to the pressure our body exercises on the foot.

Italian Footwear Solution with 3 generation of footwear manufacturing experience, we will take all the above factors into consideration while designing and manufacturing a shoe. We will also ensure to work only with the best material producers which has the same passion as us. The Comfort and Perfect Fit is our main objective, so before any design is created, we will ensure the basic designs and materials fit these criteria’s, ensuring comfort of our customer during each step pampering their delicate feet all day long. As we always say… “ Happy Feet = Happy People “.