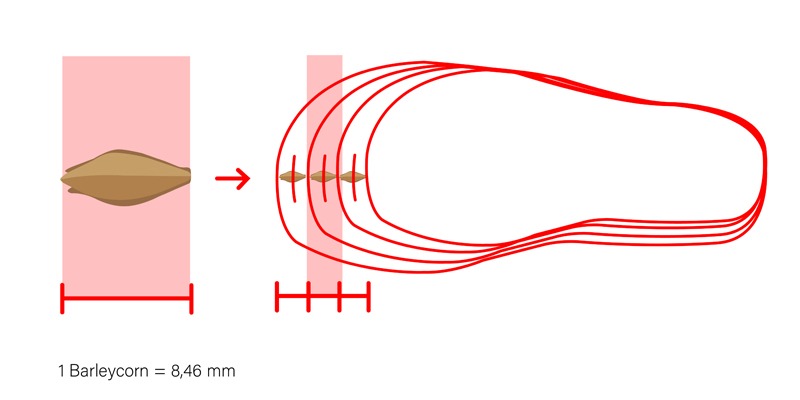

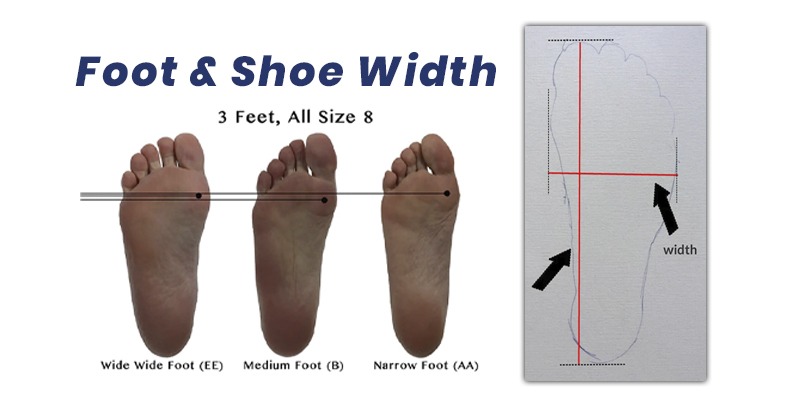

During this lesson, we will study the difference between different widths of feet and, consequently, the width of shoes. Also, here, as we saw in the previous lesson for the sizes in length, different methods depend on the country, so we will try to give an easy way to understand and calculate this width. We will discuss the three major width systems: the UK, the American, and the European. The width is defined as the fitting girth measured around the ballpoints, which corresponds to the foot’s most expansive area, found on the first and fifth metatarsal bone area.

The UK system uses alphabet coding for the width. Letter F for example, is the 6th letter of the alphabet that corresponds to the Normal fit. The French system will use the number 6 for Normal fit, which corresponds to the 6th letter of the alphabet, which is, once again, F. The American system will also use a letter system, and the Normal fit would be the letter B for women and D for men. This means that the regular fit that corresponds for the UK is the letter F, and for the European system, the number 6; for the American system, it would be the letter D for men and B for women. In the American system, instead of D & B, we can use M for medium fit, which is a regular fit.

Now that we know that the number 6 is a regular fit or F or M, we can have all the other widths by counting from 1 to 10, where a smaller number than 6 is always more narrow and larger than six is always wider.

The above table shows technical coding used by shoe technicians, designers, patterns, and last technicians. We will use a simpler version for the general public: N = narrow, M = Medium, and W = Wide. If we have a technician width table, we will notice that the ball girth in a Medium width for the standard last size eight measures 240mm. This table would give you all the widths depending on the shoe size type and for males or females.

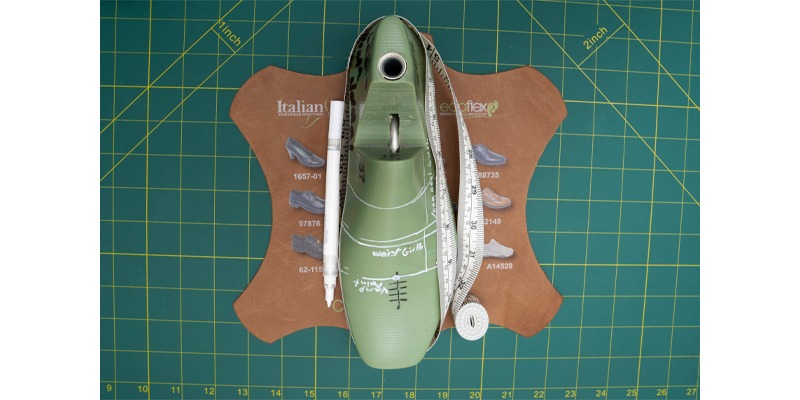

To always give a comfortable shoe fit, Italian Footwear Solution will consider a fit between the regular and wide fit, using suitable materials which will embrace the foot but have a relaxed fit allowance. This is what we call the Perfect Fit. You can always trust Italian Footwear Solution for the perfect last for a perfectly comfortable fit.

French Widths: 1 2 3 4 5 6 7 8 9 10

English Widths: A B C D E F G H J K

American Widths: AAAA AAA AA A B C D E EE

Slimmest ++ Slimer + Slimer Slimer Slim Normal Wide Wider + Wider Widest